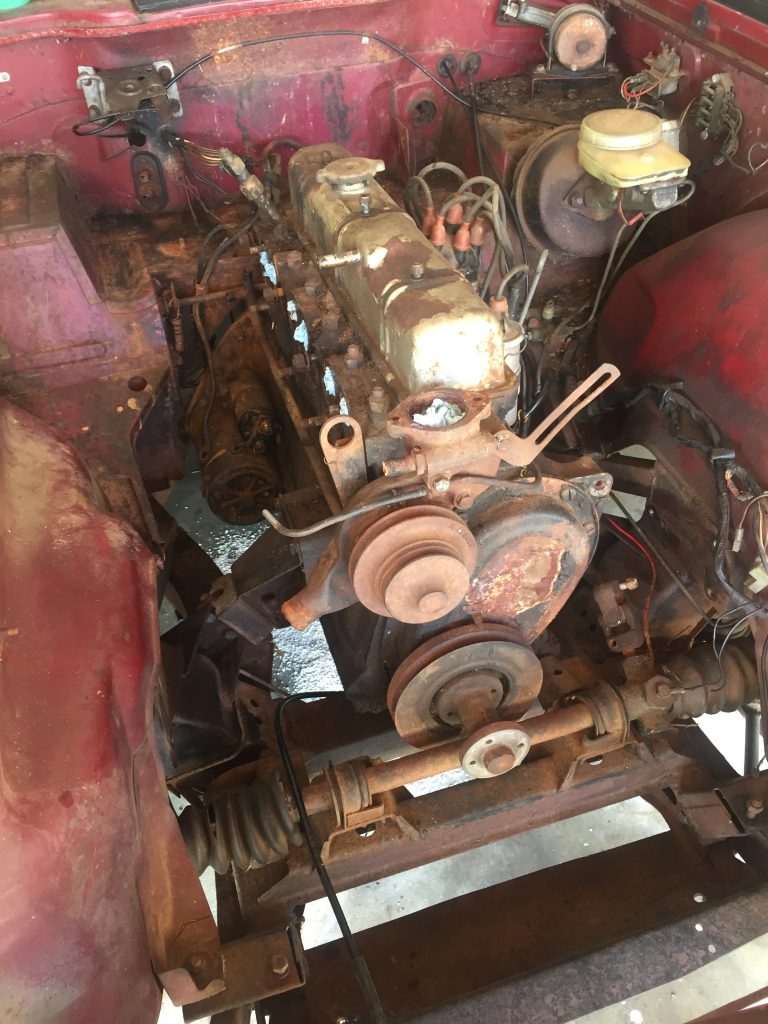

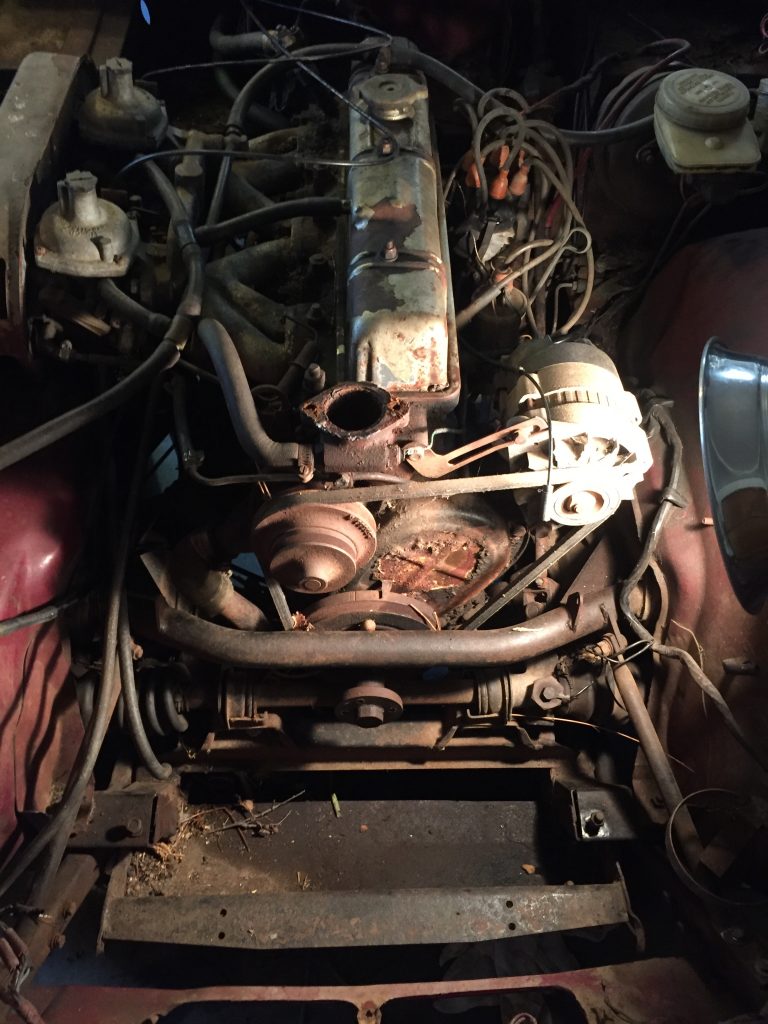

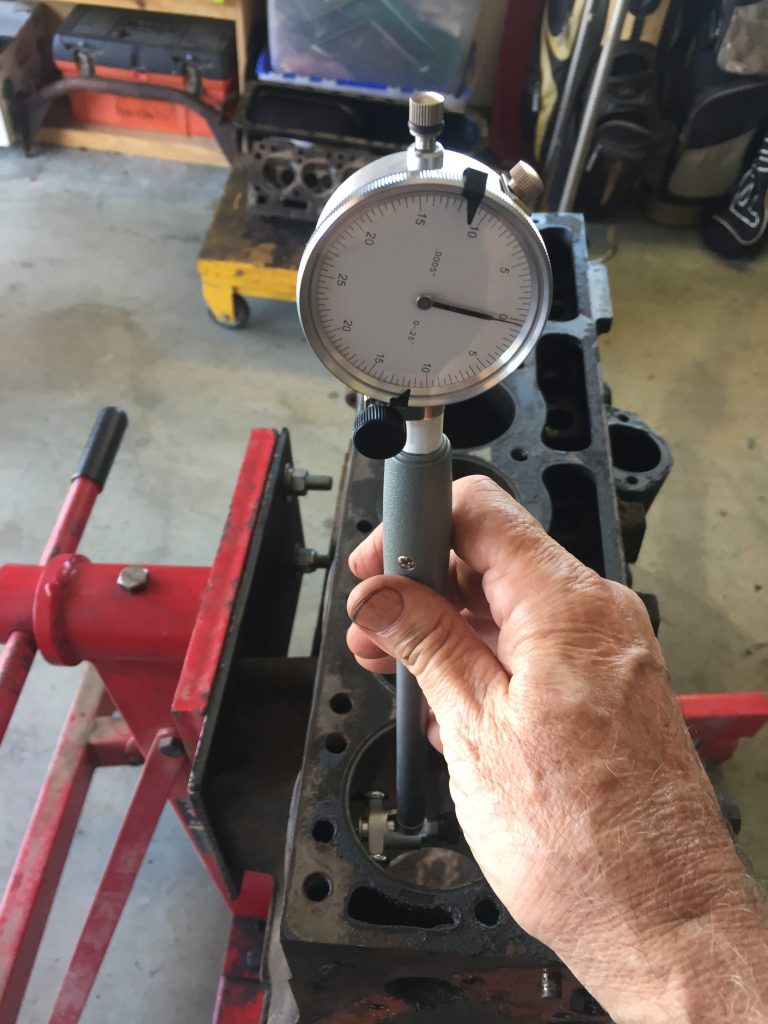

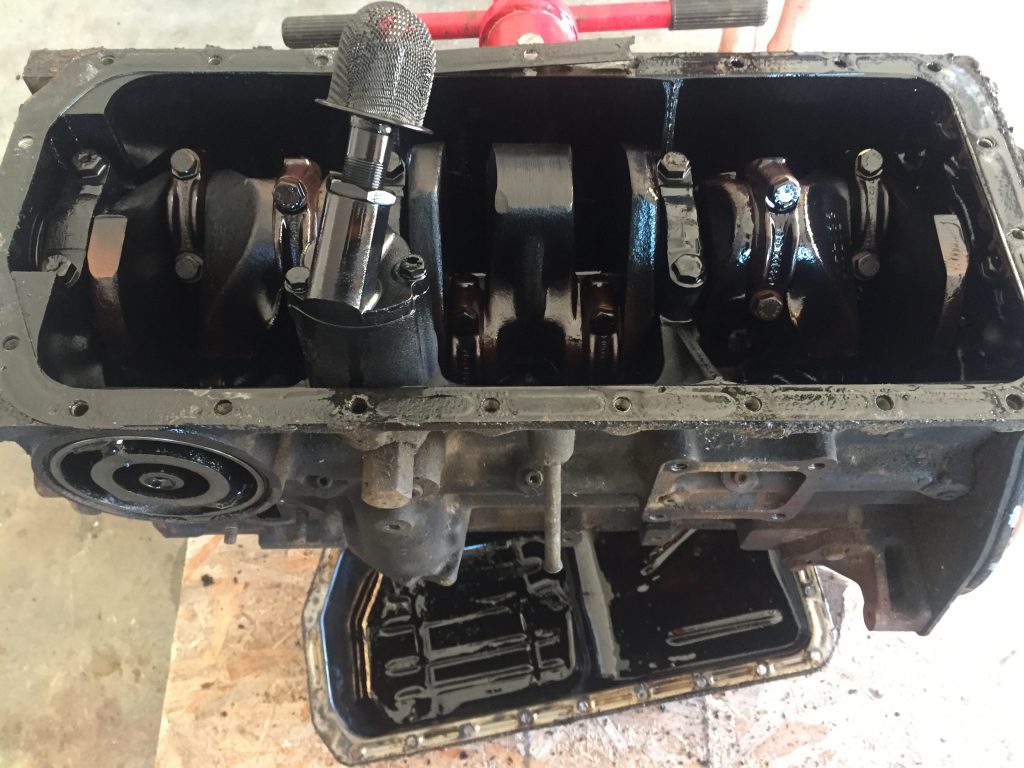

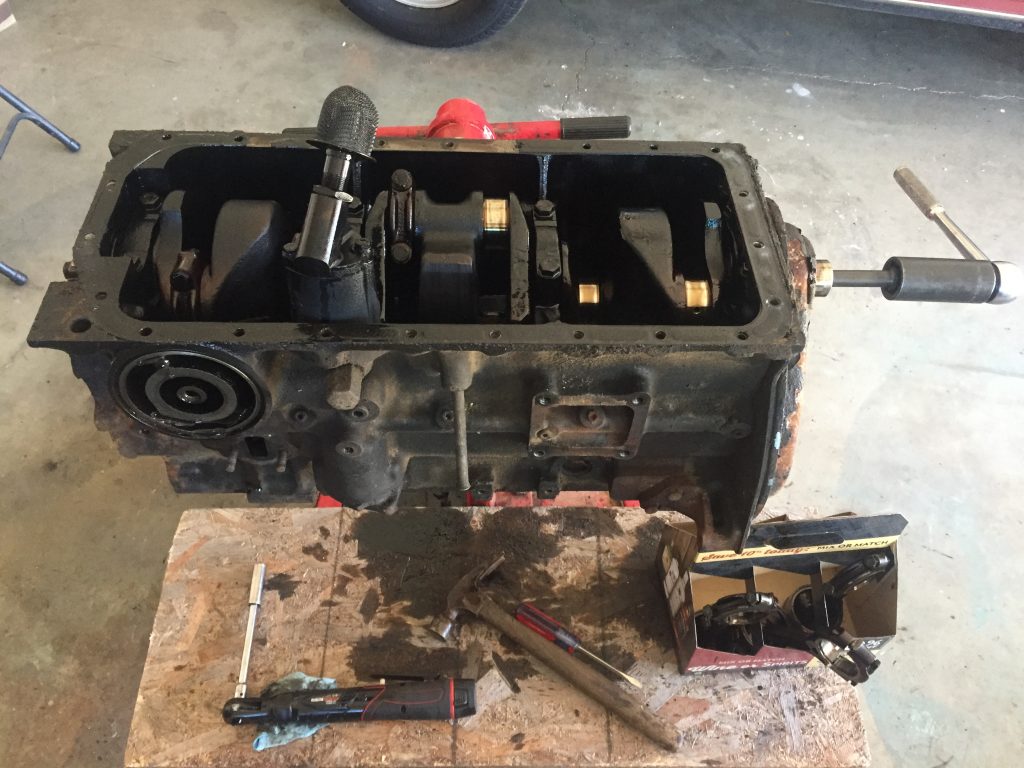

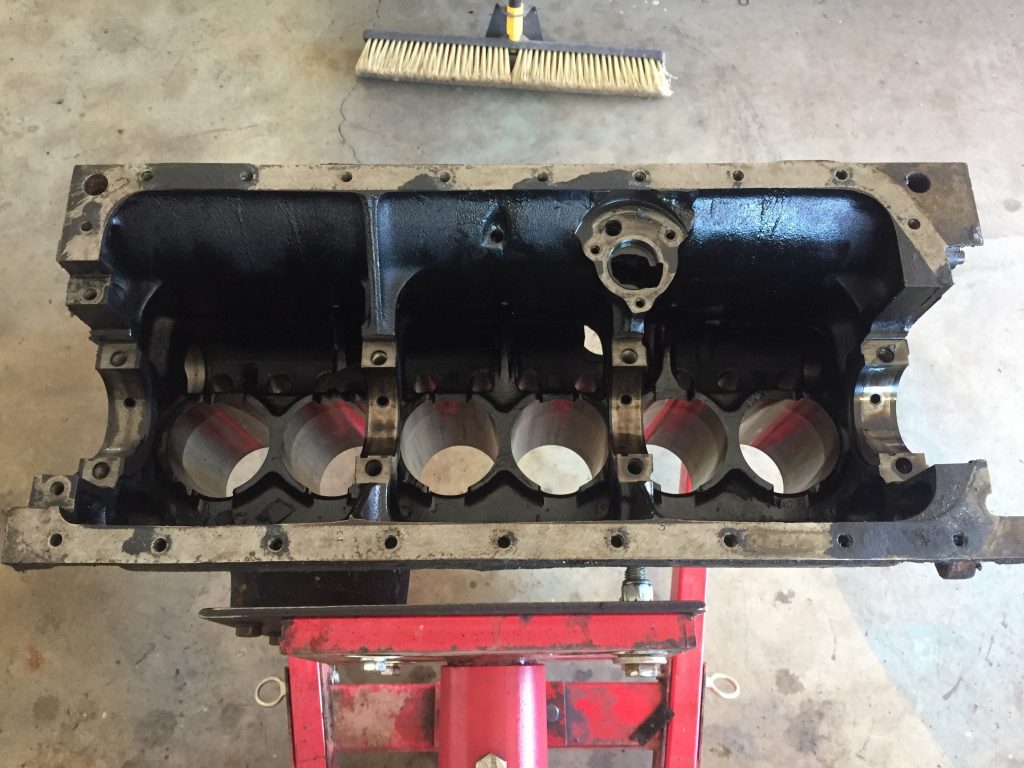

Well, everything looked as expected for an engine that probably hasn’t been freshened up since it was manufactured nearly fifty years ago. The cylinders looked fine to me, as did the pistons, but my machine shop of choice HDS/Carquest in San Marcos thought otherwise. Casey, the owner, knows what he’s doing. I absolutely trust him. Before getting the block and head over to him for the serious business, I decided to clean up the combustion chambers, ports, and connecting rods myself, as shown in subsequent posts.