Easily one of the most enjoyable parts of my rebuild was the file work on the connecting rods. I have read the stock connecting rods weigh in at 684 grams, which means I filed about 44 grams off each. My aim wasn’t lightening them, though, just wanted to remove any sharp edges, grooves, etc., that might be a point of failure by propogating cracks. HDS would restore surface strength with their peening process.

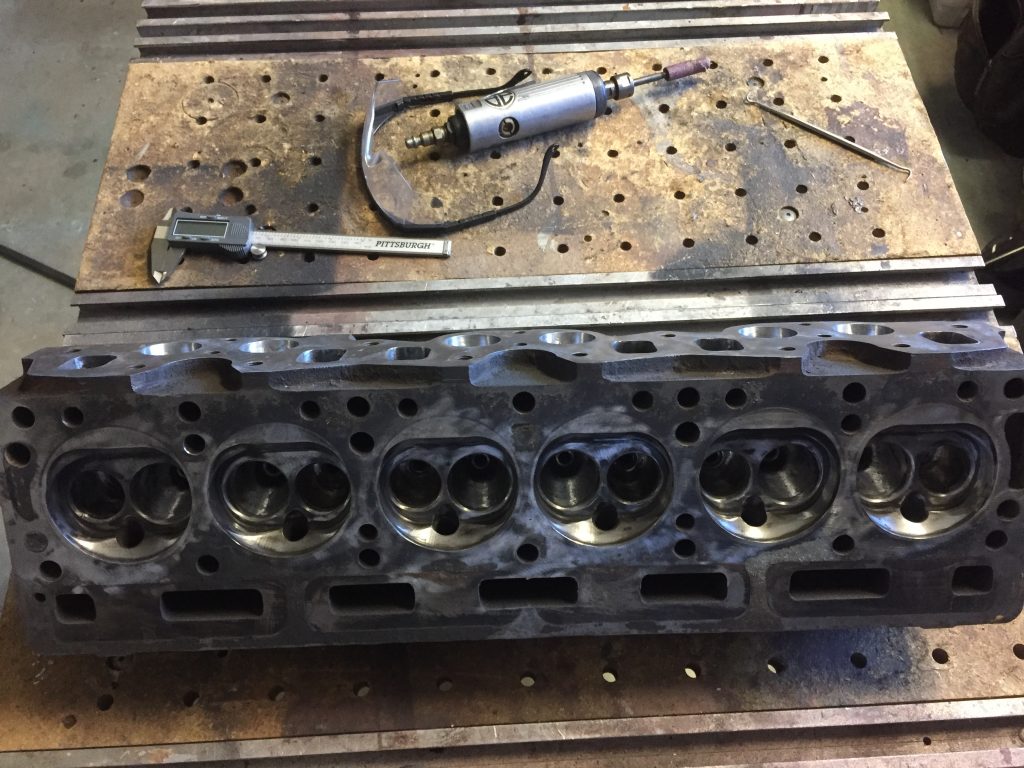

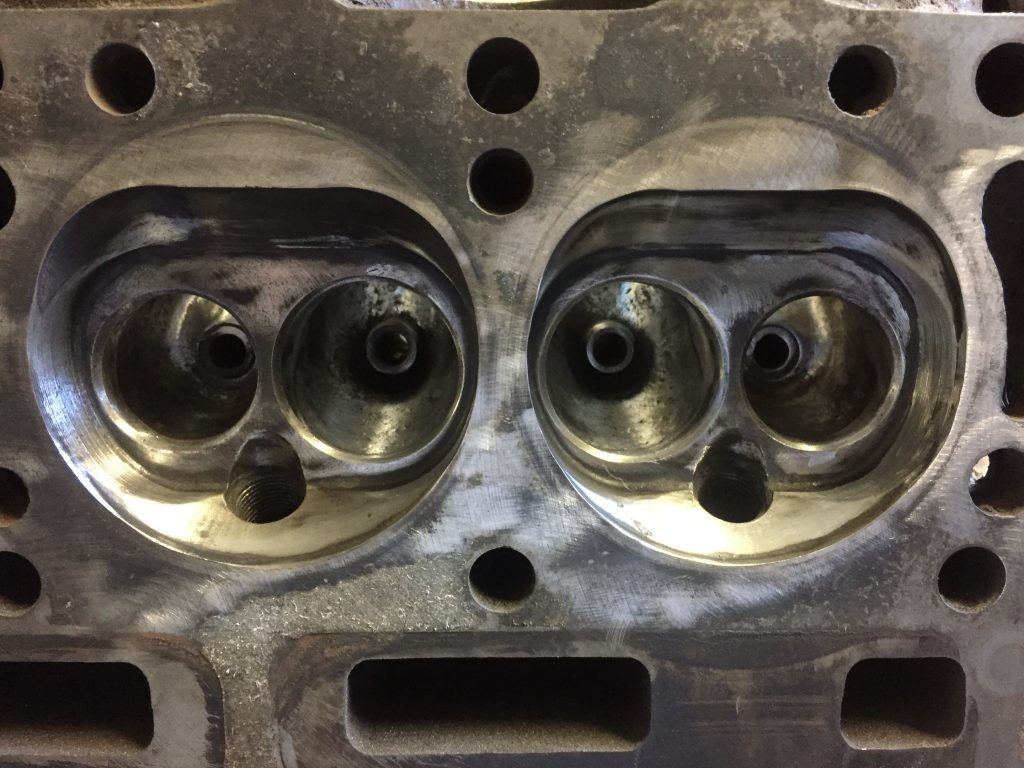

With the ports and manifolds, my goal was just to clean them up a little to aid the flow. I would advise being very careful around the valve seats… make sure you leave enough material to insert new seats and still have a nice smooth transition to the port with no big pockets behind the seats. I tried to be very conservative there.

In the combustion chambers, I was again just focused on removing sharp edges to eliminate hot spots and smooth things out a little bit. It comes at a very slight cost in terms of compression ratio since I was making the chamber a little larger in volume. I was asking HDS to lop .140 of the heads, so it was of no concern at all.