I brought the engine block and cylinder to head to Casey down at HDS Autoparts & Machine Shop in Escondido, California. Along with those heavy pieces I dropped off the following:

GP3-110 camshaft; ATI Super Damper; lightweight steel flywheel; new clutch and pressure plate; hardened valve seats; new valves; ARP head studs — all from Goodparts. I brought Casey my matched-weight set of County .020 pistons/rings/pins from Wishbone Classics. I also brought him my crankshaft; new timing gear; and my lightened 640 gram connecting rods. And probably other stuff I’m forgetting. Anyway he got the entire rotating assembly from damper to pressure plate.

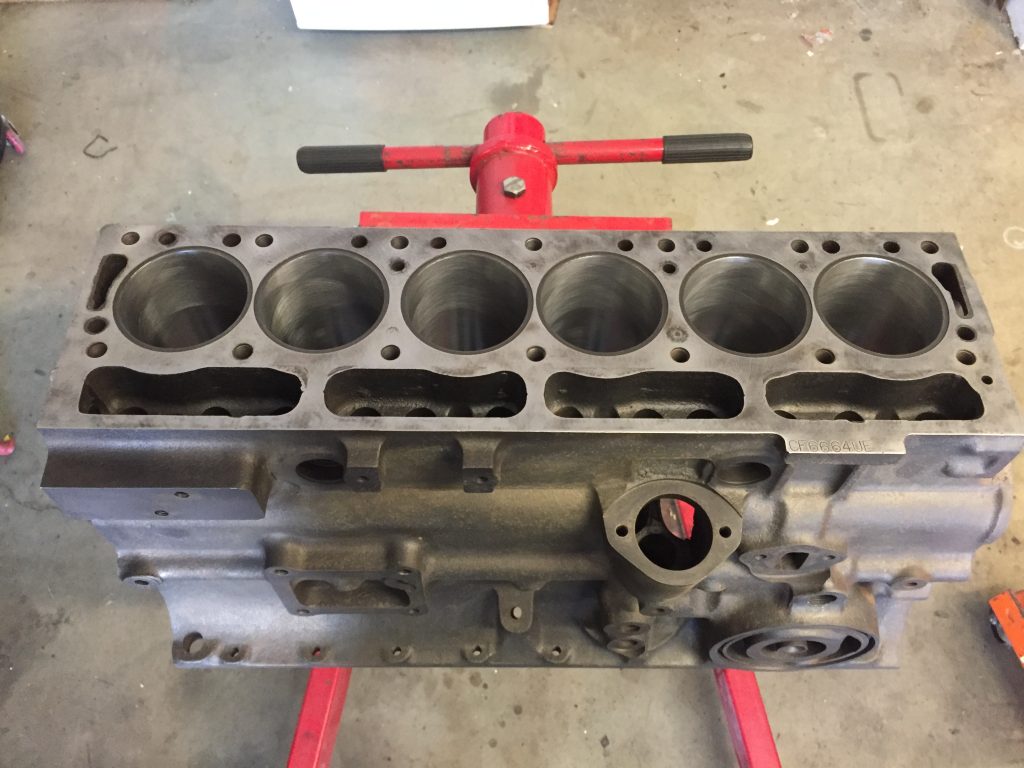

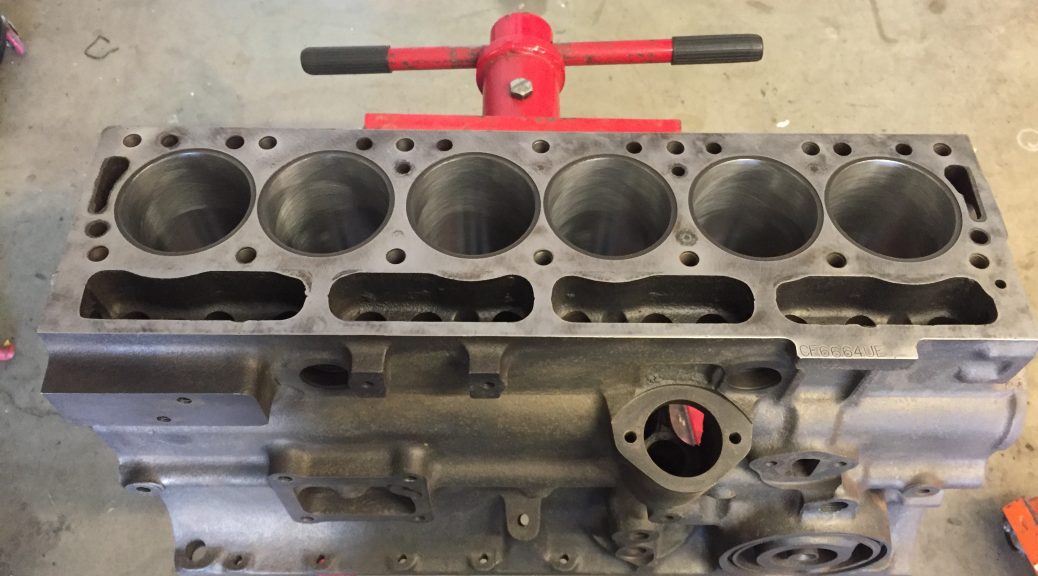

HDS cleaned and magnafluxed the engine; bored the block and installed cam bearings; bored the cylinders .020″ and surfaced the block; peened my modified connecting rods; kissed the small end of the rods; modified the rods for ARP rod bolts; installed cast iron valve guides and hardened valve seats; polished the crankshaft; machined .140″ from the cylinder head; and balanced the entire rotating assembly. The compression ratio should be in the area of 9.5:1 with the milled head.

With the matched piston and rod weights, there wasn’t much to do on the rotating assembly except for the pressure plate. As you can see from the photo above, quite a bit of drilling (metal removal) was needed to balance that puppy. Should be smooth sailing, especially with the inherent smoothness of the six.

Postscript: the spec I gave Casey for the valve guide height was from the factory manual. That was a big oops, explained in the engine assembly article later.

Wow I was just about to have my block shipped back to Richard at good parts while I was waiting for Pistons being built by JE. And I do one final internet search for some one closer that could line bore my block for cam bearings, and I come across your web page mentioning HDS in Escondido!! I live two houses out of Escondido in San Diego County. I left HDS a message with one of there employees a few weeks ago asking about the line bore and he said he would give the message to Casey and if they can do that he would call me back, I really didn’t expect they could so wasn’t surprised when I didn’t hear from them. Any how we have a lot in common. I will be going to see them tomorrow. Just about finished with the chassis. Would be great if we could talk sometime. Retired can chat anytime. Jim Ross, 661-435-3271

James, it was STUPID expensive. Casey is a good guy and I like HDS, but they had to sub out the line boring for the cam bearings and it was north of $800 as I recall. They were supposed to call me after getting an estimate but someone dropped the ball and they had the work done without my approval. We negotiated a little reduction in the charge. But I would never have spent that much if I had known before. They do good work at HDS but that one caught us all by surprise.

I would love to discuss the project, and I’m retired too… BUT tomorrow Feb 3, I’m pretty tied up with family stuff until late afternoon. You could drop by here sometime and we can bs about the cars.

Nick

Nick Jim Ross here, I’m just know seeing this response you sent me feb 2022. Because I am a subscriber I guess a notification came to my email about the question you were asked about the super Damper. That’s when I saw our exchange. Well we definitely have a few stories to exchange from the last year and a half. I never saw a response in my email and figured you had moved on to other things, didn’t think about coming back to your site. Thanks, Jim

Hello Jim, I guess I need to post articles more frequently, too. I am still enjoying the car, and just this week it has finally become t-shirt weather for my cruises. What did you decide regarding he camshaft bearings? Are you up and running with the car yet? Up here in Hidden Meadows there’s a big neighborhood fair once a month and last time (a week ago) there was a TR6 parked there, same color as mine but with a nice paint job. Looked fantastic and made me regret my decision to leave the original paint on the car. Some day I might do the paint job.

I thought if and when you replied it would also come to my email, I guess because you put down your email address when you fill out your information. Anyway basic answer I had my block cut for cam bearing through HDS as you did. The car is 95 percent done, waiting for leather seats from Rem Bros. . I’m Going for a cruise to UK,in a few days. We will get together when I get back and I will discuss the long version, if you would like.

sounds good

Hello Nichola.

What model of ATI Super Damper is this? IS there a part number written on it or the box? I’m trying to cross reference this p/n to whatever other alternative vehicle it was originally used on, so I can see if I van get a Fluidampr from a similar vehicle to use instead.

Thanks,

AJ

AJ, that damper is buried so deep in the engine bay, there’s no way I can see any part number on it without some disassembly. I bought it from Goodparts, and I just checked their website and that’s no help… just Richard’s part number. I’ll do a little online research. Good luck!

I’ll take a look to see if I kept that box.

No box, AJ. Looking at photos from my build the only numbers visible are the SFI Spec 18.1, and then below that “A 991171”