In my preteen years, I would sit in bed with Road and Track magazine reading about my Formula 1 heroes. Then I would grab my protractor for a steering wheel, a pencil for a gear shift lever, and imagine myself racing. A bit more than six decades later the dreams are now memories. It’s just the TR6 and me.

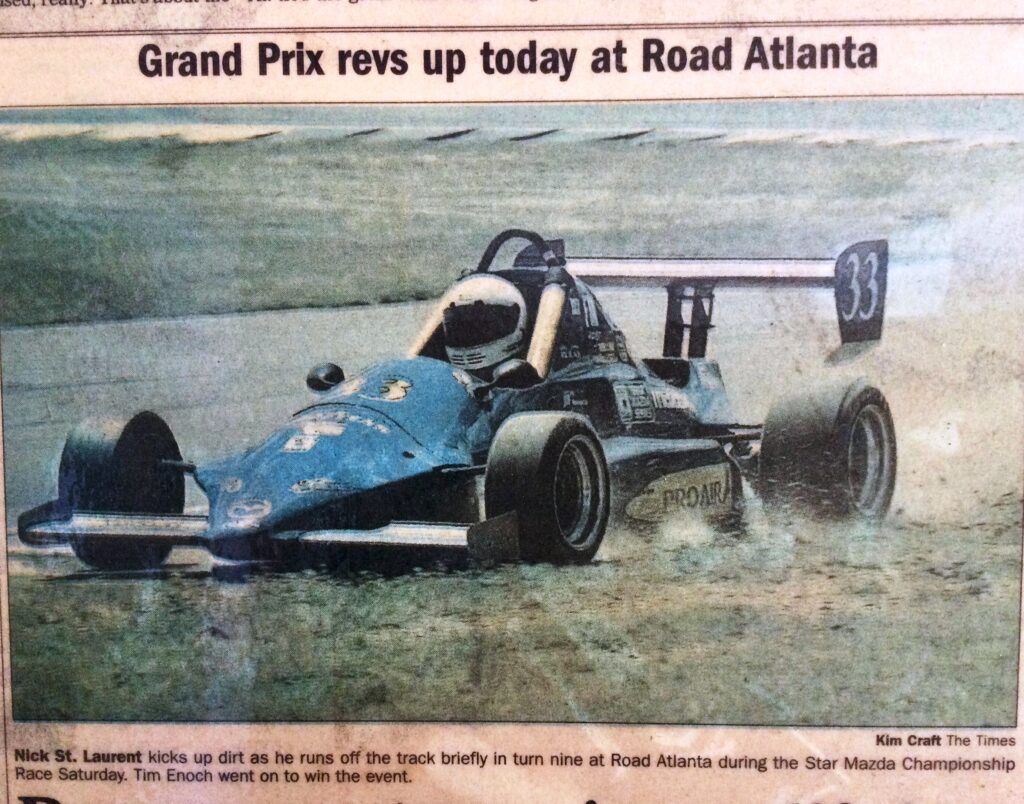

In my dozen years of racing motorcycles, and another dozen years racing on four wheels, mostly SCCA formula classes, FF, FC, and FM, I managed to retain a single in-car video. This is from my one and only weekend racing a Spec Racer Ford, rented from my friend Tom Dalrymple, who owned a small fleet of them. Back then, the cars were pretty slow – perhaps 10 seconds a lap slower than an FF car on this particular circuit – but the racing was close and loads of fun. A major difference between formula car (open wheel, single seater) racing and SRF racing is that the latter is definitely a contact sport, as I found out on this weekend. Didn’t quite make it to the finish line…

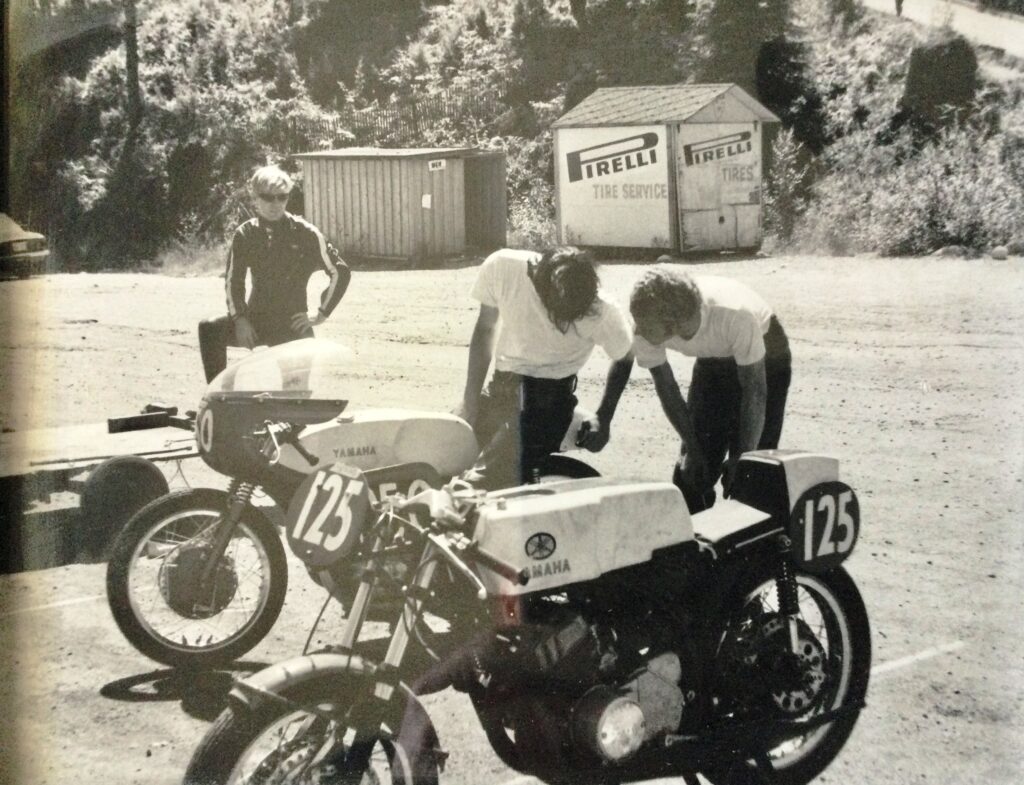

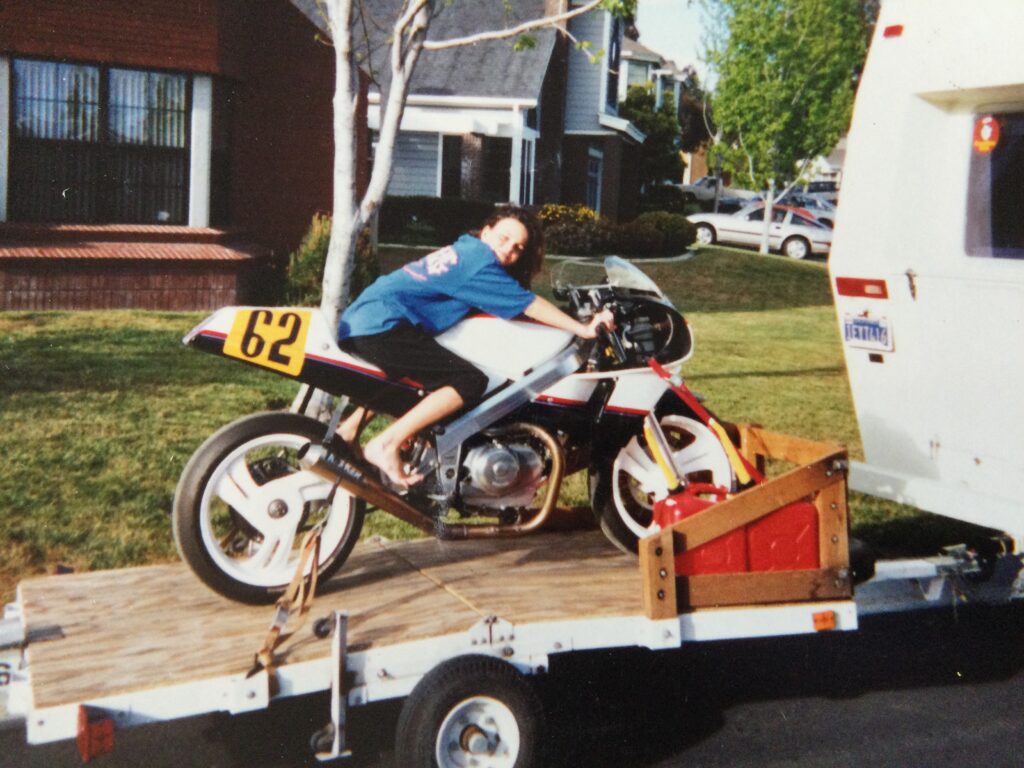

Below is a gallery of my race cars and bikes. The Lotus 23 and Mini Cooper photos are not my cars but mine looked the same as these two, including the colors. In fact, the Lotus might well be the one I raced, and then sold on after I switched from CVAR vintage “racing” to proper racing with the SCCA. Click on the “i” button for the full captions.

There are so many stories for each of these racing machines. Eventually I’ll add a post about each of them.